P-000001 Fiat 500 Abarth Cabrio Torsion Bar Mounting Bracket

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

One of our racing partners, @toplessracing, came to me with a problem; he snapped his custom torsion bar mounting bracket while driving home from work. Without even so much as one race on the bracket, it had completely failed. I told him, “Sure thing! We can design a stronger and more functional part.”

So, the first step, is research. Why did it fail? The next step, is problem solving. How can we improve on the design? And the final step, is production. How can we manufacture a new part at race-quality with minimal cost?

Why Did It Fail?

- The material used was billet aluminum, scrap billet aluminum, to be precise, and was of unknown composition, but is believed to be a generic 6061 alloy.

- Aluminum is lightweight and strong, however, fatigues easily under constant load cycling.

- Since the aluminum is scrap, it is possible it could of overheated during the machining process.

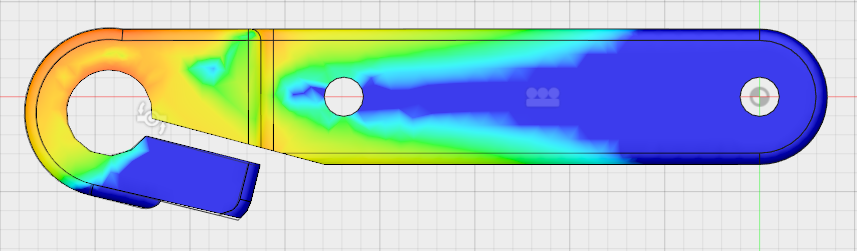

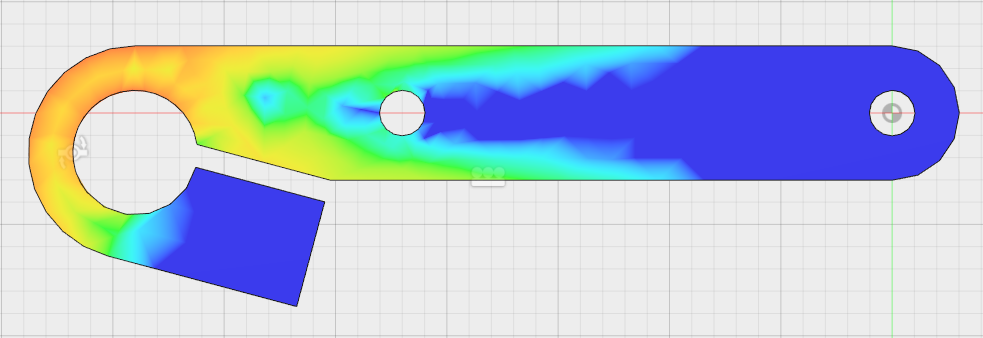

- The shape of the part, as seen in the animation above, has two major flaws that concentrate the force directly into a 90-degree corner. This gives the material a very predictable starting point for a fracture.

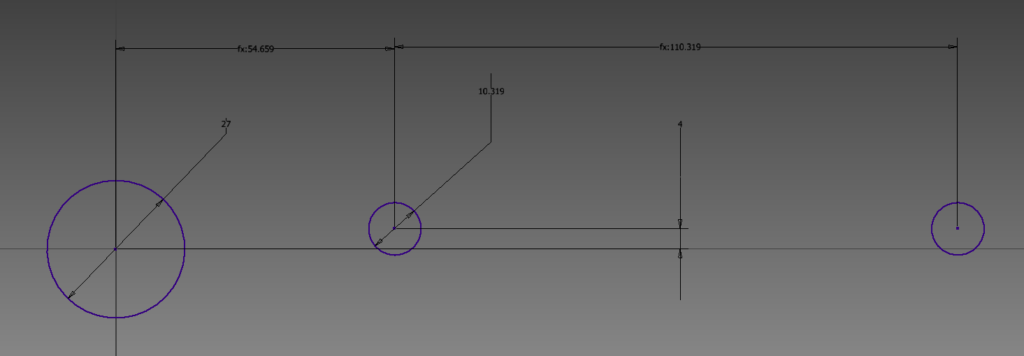

- The part secures itself to the torsion bar by clamping down onto the 28mm rod end, using a 27mm hole with a knurled surface, and two steel bolts. While this is fine, the placement of the mounting bolts, and the separation angle of the two halves, allows the Moment forces from the torsion bar to concentrate into a massive load at the fracture points.

- The FEA assembly simulation failed at a torque of about 50 ft-lbs, fracturing at the two surface defects where the forces were concentrated into a corner.

How Can We Improve The Design?

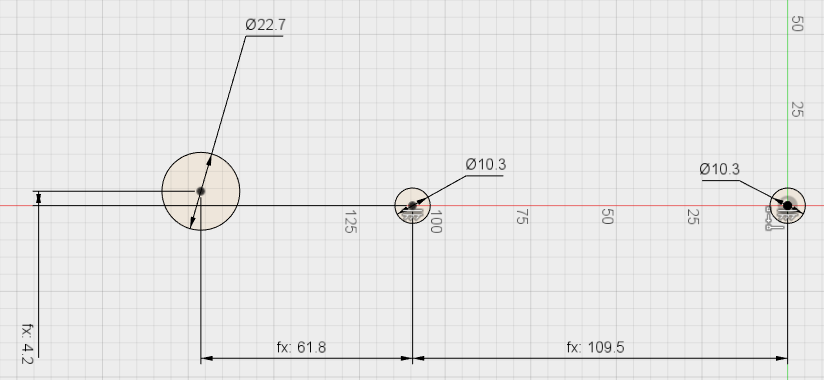

In order to improve a design, you must first look at previous efforts. In this case, you would have to be insane to ignore the millions of dollars of research that Fiat poured into this vehicle. So, our first step is to reverse-engineer the original Fiat Part # 68158719AD.

The goal with creating a CAD model of this OEM part, is to get a basic hole layout and to run an FEA to determine how strong the part is. Then, we will remove all the geometry except for the holes, and design a new part that will exceed the original strength.

The results of the OEM part show two times the strength of the failed custom bracket. So now, we have a goal of about 100 ft-lbs of torque for our final part strength. We then clear out all of the OEM geometry, and end up with a basic starting point for the new design.

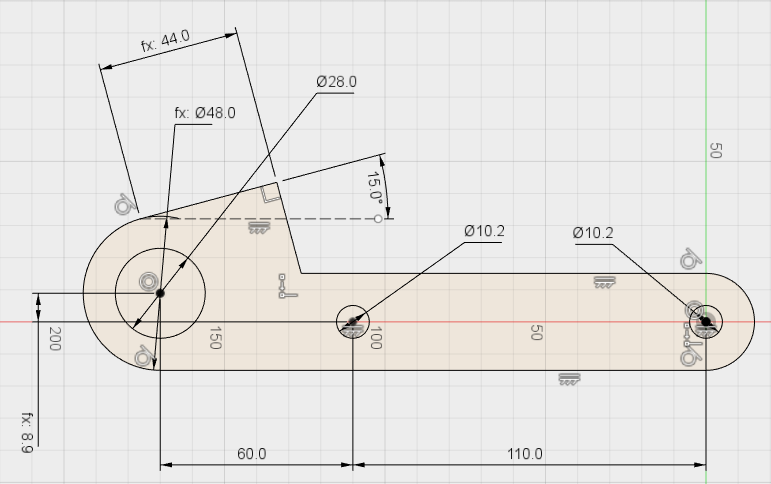

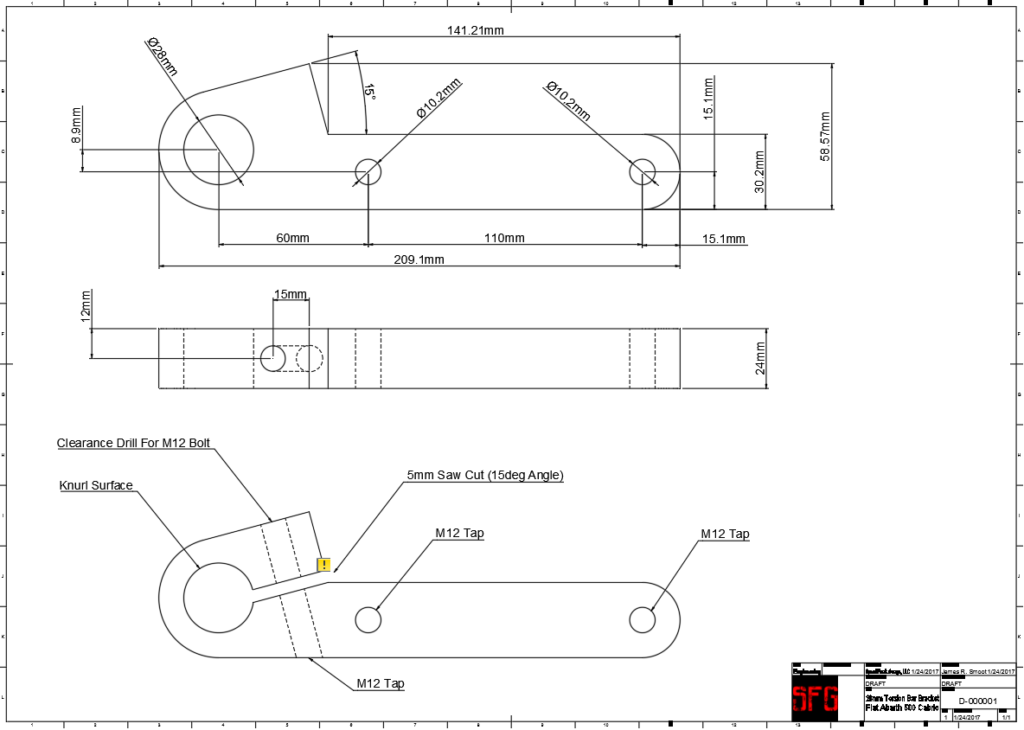

The next step is to modify those hole sizes to fit the 28mm torsion bar upgrade, and to correct some minor errors in the tap drill size on the threaded holes. Afterwards, we can build a new structure to encompass this base geometry.

After finishing on the sketch, we chose to use the same M12 bolts throughout, and created a 3D model with an overall thickness of 24mm. We also simplified the clamp portion, while making a point to lower the torsion bar location relative to the vehicle, and to reduce the overall footprint of the mounting bracket. Instead of using Cast Steel, the part will be machined from High Strength Steel, which should result in superior durability.

After running the analysis on the new design, we find that the part is much stronger, even though our clamp hole size has been increased by 6mm to support the 28mm torsion bar. The next step is to prepare drawings, so that a machine shop can build test parts.

After the machine shop worked with the new design, we tested it on the vehicle.

(Pic Here)

(This post is currently under construction, please excuse our mess.)

You are welcome to download the high-resolution CAD files HERE (add link when complete). Please be sure to respect my CC-BY-NC-SA license. Thank you for your understanding.

(Pic Here)

Warning! All products and services are for off-road use only. Use at your own risk. Please read our full disclaimer.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License